AP200 Pouch Label Applicator

$2,800.00

2,400 EUR

7.87 in (200 mm)

9 in (230 mm)

All roll label printers

The gist:

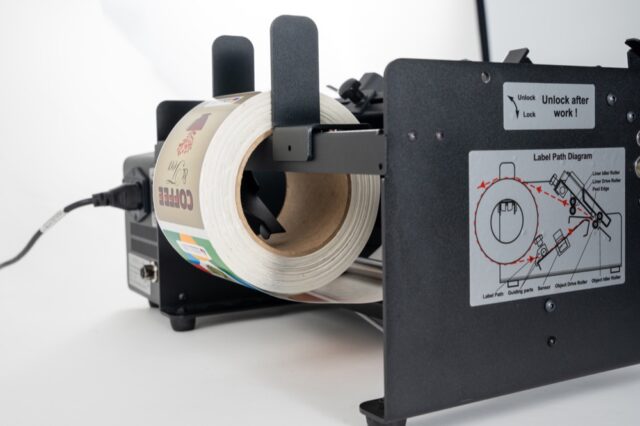

The AP200 is a semi-automatic labeling machine designed for applying labels to flat unfilled pouches. Both single and front-and-back labels can be consistently applied by simply dropping a pouch into the machine.

Top Uses & Applications

Easily and consistently apply labels to pouches

The AP200 is a semi-automatic labeling machine designed for applying labels to unfilled pouches. Labels are easily applied as each pouch is dropped into the machine. Intuitive setup and operation allows for consistent placement and even application.

The ultrasonic media sensor is easily trained to detect gaps in a wider range of media than mechanical flag sensors common in other applicators, allowing the AP200 to perform consistently—even on thin, clear, or reflective materials.

A convenient calculator tool is available to make correct settings easy.

- Designed for flat, unfilled pouches

- Apply one or two different labels per container

- Works with zippers and degassing valves

- Reliable ultrasonic gap sensor

AP200 Details

Specifications

Technical Data | |

|---|---|

| Supply voltage | North America - 110V AC, 60 Hz — Europe, Middle East, Asia - 220V AC, 50Hz |

| Power consumption | <100VA. |

| Dimensions | 17.3" (440mm) W, 9" (230mm) H, 13" (330mm) D |

| Machine weight | 33 lbs (15kgs) |

| Width of Bag | 3.2" (80mm) to 9.8" (250mm) |

| Length of Bag | 4.75" (120mm) to 13.75" (350mm) |

| Thickness of Bag | <0.2" (5mm) |

| Width of label | 1" (25mm) to 9.00" (230mm) |

| Length of Label | 1" (25mm) to 11.81" (300mm) |

| Label gap | >0.1 inches (2.5mm) |

| Diameter of label roll | <7.87 inches (200mm) |

| Core diameter | 2 to 3 inches (50 to 76mm) |

| Label feed speed | 0.03 to 0.1m/sec - programable. |

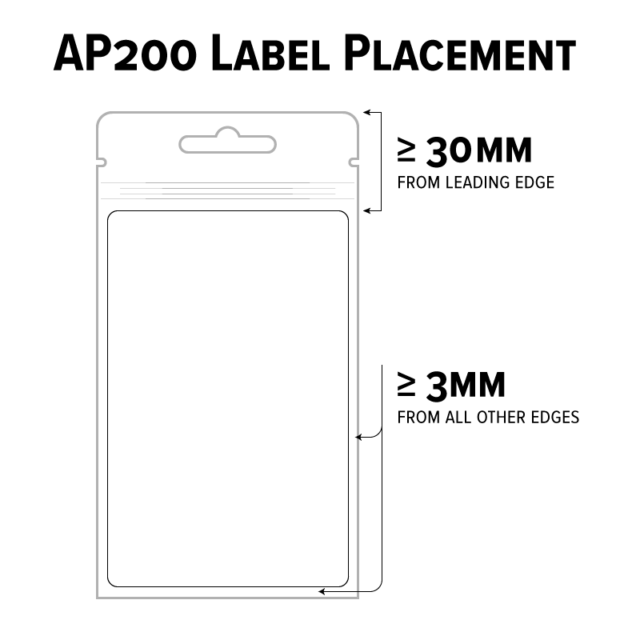

| Distance to start labeling from the edge of the bag | Approximately 1.18" (30mm) |

| Modes | 1 or 2 label modes |